Our Competitive Advantage

Universal Matter, Inc. is commercializing a new patent-pending process to become the world’s leading supplier of the most economical and high-quality graphene that is also turbostratic in nature. This new process can also utilize a very broad range of carbon-based feedstock materials, including recycled plastics and biomass. This technology and additional developments are expected to support broad adoption of graphene across several major industries. Our proprietary commercial process is based on an invention by Dr. James Tour professor of organic chemistry and nanotechnology at Rice University in Houston, Texas and co-founder and scientific advisor to our company.

- This classification framework provides a categorization of different graphene types according to three fundamental graphene based materials properties: number of graphene layers, average lateral dimension, and atomic carbon/oxygen ratio. The different materials drawn at the six corners of the box represent the ideal cases according to the lateral dimensions and the number of layers reported in the literature.

- Most bulk-scale graphene is produced by a top-down approach through the exfoliation of graphite, often requiring large amounts of solvent with high energy mixing, shearing, sonication or electrochemical treatment. While chemical oxidation of graphite to graphene oxide promotes exfoliation, it requires harsh oxidants and leaves the graphene with a defective perforated structure upon the subsequent reduction step. Most of the current graphene structures entering the market are more closely related to “graphene nanoplatelets”.

- Here we show that flash Joule heating (FJH) of many inexpensive carbon sources, such as coal, petroleum coke, biochar, carbon black, discarded food and mixed plastic waste can produce turbostratic graphene (TG). The process uses no furnace and no solvents or reactive gases. The turbostratic graphene structures that result from this process are more closely related to “graphene nanosheets” from a structural perspective.

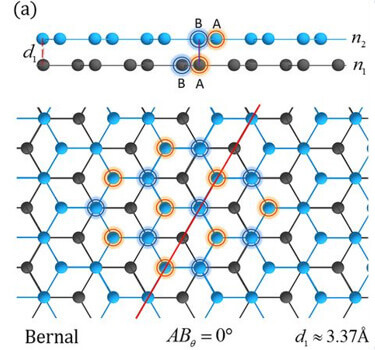

Bernal Stacking – typical graphene

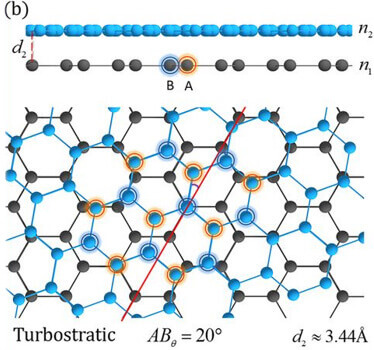

Turbostratic Stacking – Universal Matter graphene

a) AB-stacked (Bernal)

b) turbostratic graphene

- The rotational stacking of turbostratic graphene helps mitigate interlayer coupling and increases interplanar spacing, thereby yielding superior physical properties relative to competitive graphene structures when compared on a similar weight basis. The subtle difference in adjacent layer stacking orientation expresses itself with important differences in product performance attributes. One important performance benefit evident with turbostratic few layer graphene (FLG) is that the bilayer and trilayer structures separate into individual layers more easily and they tend not to recouple

- Therefore, lower quantities of few layer graphene (FLG) can generate the same structural performance gains, better electrical and thermal conductive properties.

- Multilayer graphene with relative rotations between carbon layers, known as turbostratic graphene, can effectively decouple the electronic states of adjacent layers, preserving properties similar to that of single layer graphene (SLG).

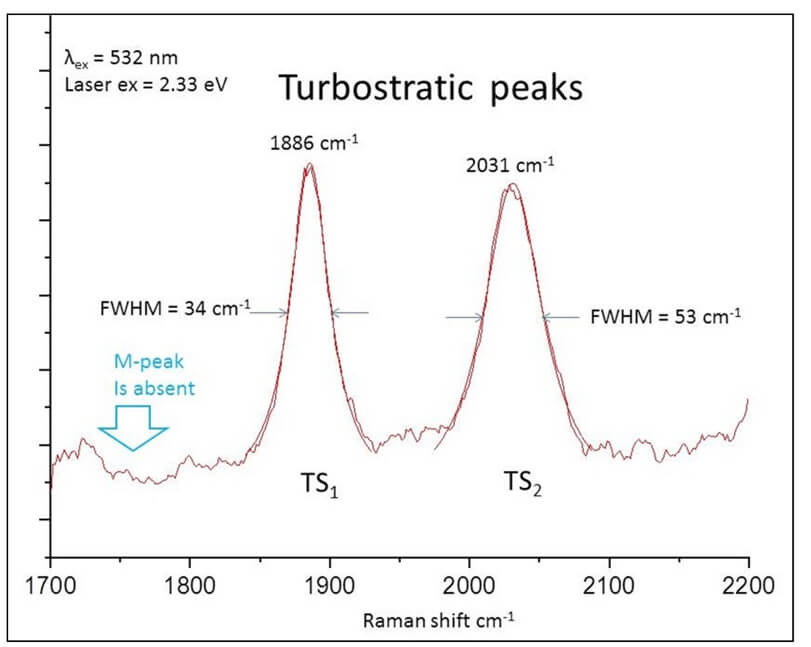

The turbostratic stacking of Universal Matter flash graphene is definitively shown by the two Raman spectroscopy peaks, TS1 and TS2, with the requisite missing M-peak.

- By Raman spectroscopic analysis, TG shows a low intensity or absent D band with I2D/G reaching more than 10 and sometimes even 17, making FG among the lowest defect graphene ever reported. The turbostratic nature has been observed by powder X-ray diffraction (XRD) analysis, meaning that is has little order between the graphene layers, thereby facilitating its rapid xfoliation upon mixing during composite formation.

Turbostratic Graphene-Superior Dispersibility

- Commercial

- Graphene

- 15-30 layers

- 0.2 g/l

- 0.02%

Commercial graphene dispersion after 8 hours

Turbostratic Graphene dispersion after 6 months

- Turbostratic

- Graphene

- 1-5 layers

- 5.0 g/l

- 0.5%

Environmental Advantage

- Graphene has the potential to provide a significant environmental advantage to the human race by strengthening, and therefore reducing the volume used, of many of the raw materials we use every day: concrete, asphalt, plastics, rubber and paint to name just a few. For applications where the volume cannot be reduced, graphene promises to significantly improve the life cycle of products. For example graphene in asphalt has been shown to increase the life of a road by 300%. Universal Matter will deliver all of these advantages with less graphene thanks to its superior purity and dispersibility. The uniform distribution of graphene through the material it is aiming to enhance is key to delivering the superior properties and durability.

- The combination of reducing the use of primary materials like concrete through the use of graphene and making the graphene from renewable or recycled feedstocks, hold enormous potential to both reduce the human footprint and curtail global warming through the reduction of GHG emissions.