About Universal Matter

Universal Matter facilities in Canada, United States and United Kingdom

Corporate Headquarters:

· New product and application development lab

· Initial Production Facility (IPF)

. Annual capacity to deliver:

. 40 M liters Genable™ Decarb = 20 M m3 Concrete

. 75,000 mt of Genable™ Pave = 2.5 M mt Asphalt

USA Subsidiary:

· Process, product & application development lab

· Lab/Pilot production: up to 20 kg/day of graphene/graphitized carbon

UK Subsidiary:

· Process, product & application development lab (focus: Paints & Coatings; Composites)

· Production: Graphene dispersion capacity of ~72 mt/year

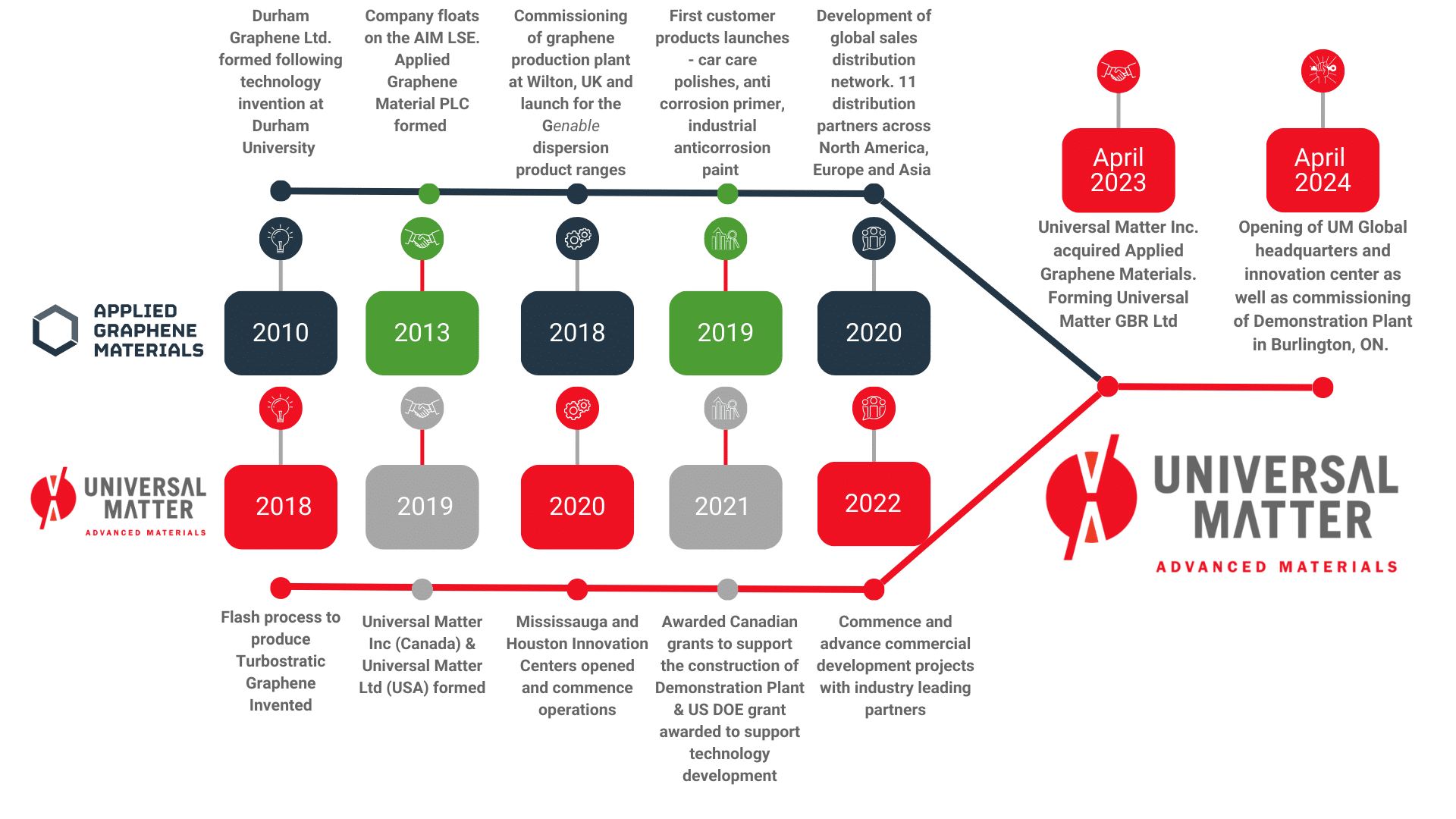

The Evolution of Universal Matter's UK Subsidiary (UK GBR Ltd)

The world leader in graphene nanoplatelet dispersions for paints & coatings applications

Universal Matter GBR Ltd (formerly Applied Graphene Materials) is proud to be a leading innovator in graphene dispersion and application technology. We are proud to be the industry-leading organization that is truly harnessing the potential of graphene in real-life products and materials. Taking a substance that is difficult to work with and creating stable, standard dispersions that are easy to formulate with and produce consistent, reliable results for customers. We are experts in helping our customers choose, or create, the perfect graphene nanoplatelet dispersion to meet their needs.

POTENTIAL FOR GHG REDUCTION AND INDUSTRIAL UPCYCLING (INDUSTRY 5.0)

Upcycling, also known as creative reuse, is the process of transforming by-products, waste materials, useless, or unwanted products into new materials or products of better quality and environmental value.

The flash graphene process can convert inexpensive carbon sources, such as coal, petroleum coke, methane derived carbon, and carbon black into graphene/graphitized carbon. Additionally, previous waste or low value recycling streams such as bio based waste, tire waste, and mixed plastic waste can also be effectively converted into graphene via this new process. Finally, this process uses no reactor/furnace, no solvents and no reactive gases.

The flash graphene process can convert inexpensive carbon sources, such as coal, petroleum coke, methane derived carbon, and carbon black into graphene. Additionally, previous waste or low value recycling streams such as bio based waste, tire waste, and mixed plastic waste can also be effectively converted into graphene/graphitized carbon via this new process. Finally, this process uses no reactor/furnace, no solvents and no reactive gases.

Our expertise

Universal Matter’s patented breakthrough Flash Joule Heating (FJH) Technology provides cost-effective production of high-quality graphene/graphitized carbon at industrial scale. FJH creates high quality graphene with 3 distinct morphologies providing our graphene with superior properties that are critical for large industries. Unlike our competitors with only 2D morphology, 1D, 2D, and 3D tunable morphologies from FJH adds critical value to high volume industrial applications while reducing their carbon footprint.

Of equal importance is our ability to disperse the graphene in a variety of liquid or solid mediums that are safe to handle, provide easy incorporation into downstream industrial products, and ensure an effective interaction with other key materials in the final product. This is the key to achieve breakthrough performance in the final markets/applications.